When a team is under pressure to hit daily targets, the last thing they need is a workstation that forces them to work around it. In many facilities, the workbench becomes an accidental bottleneck, slowing down an otherwise well-planned process. The height is almost right, but not quite. The tools are close but never close enough. The lighting works most days but creates shadows on the days when precision matters most.

A well-designed industrial workbench should be an extension of your process. Not an obstacle. Something that helps your team move confidently and consistently through each step.

Start With the Real Workflow, Not Assumptions

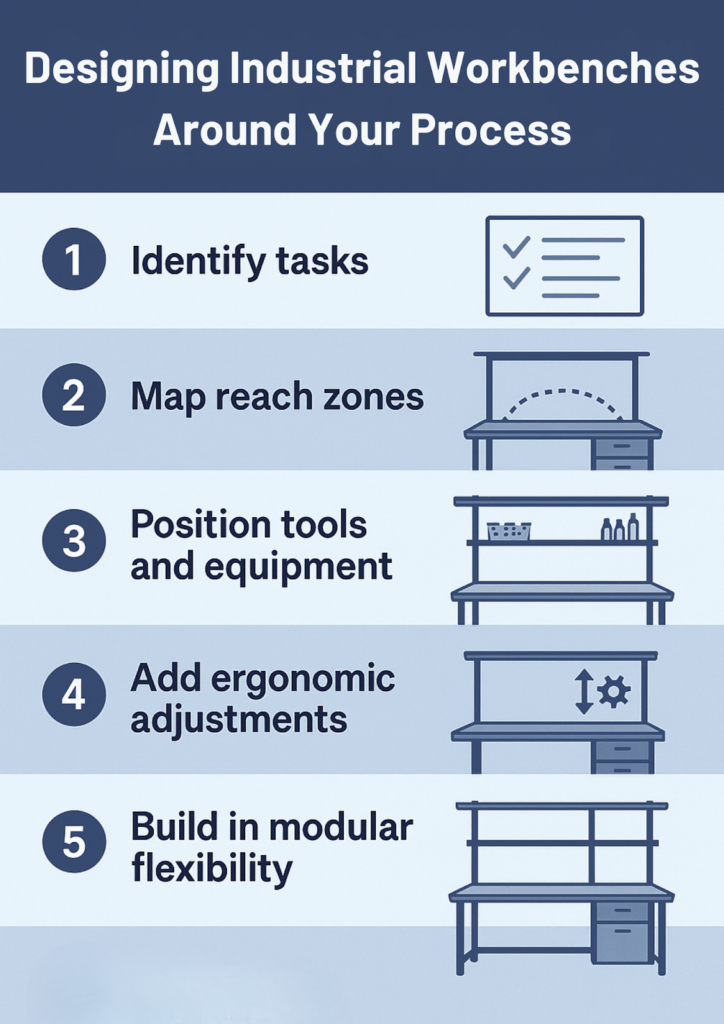

Every operation has its own workflow. A biotech assembly line looks very different from a semiconductor inspection cell. Aerospace technicians organize tools differently than medical device teams, where cleanliness is paramount. These differences matter. When a workstation is designed around the actual sequence of tasks, teams spend less time reaching, searching, or making adjustments. That shift pays off every day by improving comfort, increasing speed, and reducing errors.

Good design begins with questions, not catalogs. What happens first in the sequence? What equipment must stay within arm’s reach? Where operators are most likely to strain or repeat motions. What will change as the process evolves? When those answers guide the layout, the workstation fits naturally into the environment.

Ergonomics is the Quiet Productivity Booster

Comfort is the foundation of repeatable work. Height adjustability gives teams control. Proper lighting keeps eyes fresh and reduces the need for rework. Storage placed strategically reduces fatigue over long shifts. These details create an environment where people can work at their best without feeling constrained by their station.

There is no universal ergonomic standard across industries. The best approach is to make adjustability predictable and straightforward so each operator can fine-tune the setup for their build style. When people can work comfortably, quality improves and morale tends to follow.

Flexibility Keeps Your Operation Future-Ready

Every industry changes. Product mixes shift. New tools arrive. Cleanliness requirements tighten. A workstation built too rigidly becomes outdated the moment your process evolves. Modular design solves that problem. Shelving, power options, articulation arms, and storage can be adapted as new demands arise. The bench shifts with you.

This approach keeps facilities nimble. It prevents expensive overhauls and protects teams from outdated setups. Most importantly, it supports continuous improvement because you are not locked into yesterday’s layout.

Collaboration Makes the Design Better

Workstation design works best when you are actively involved in the conversation. You know your process better than anyone. Your insight is the reason the final bench will work. Instead of forcing you to choose from a limited set of templates, a collaborative approach translates your needs into a practical and durable solution that feels familiar from the start.

Clear communication makes the design phase straightforward and predictable. You explain the workflow. Together, you adjust the details. The result is a workstation that supports the team from the moment it arrives.

Ready to improve your workflow?

If you are exploring custom industrial workbenches that precisely fit your process, Bench-Tek can help you map out the layout, options, and modular features that support your team’s day-to-day work. Share your workflow priorities, and we will help you shape a bench that feels intuitive from the start.

Key Takeaways

- Build the bench around the workflow.

- Keep ergonomics adjustable and straightforward.

- Select modular features that scale with your workflow.

- Involve your team in the design.

- Aim for a smoother workflow and reduced operator strain.