In any production environment, whether it is a biotech lab, an aerospace assembly line, or a precision electronics facility, the workspace shapes how efficiently people can do their jobs. When every task requires focus, precision, and consistency, the layout and design of a workstation are more than just details. They determine how smoothly a process flows and how effectively a team can work. That is why custom workbenches are often described as the backbone of efficient operations.

A well-designed workbench does more than hold equipment. It supports workflow, safeguards product quality, and helps employees maintain comfort and productivity. Off-the-shelf benches might meet basic needs, but they rarely align perfectly with a specific team’s process or space. Custom workbenches, by contrast, are built around how people actually work. They turn workspace design into a strategic tool for efficiency.

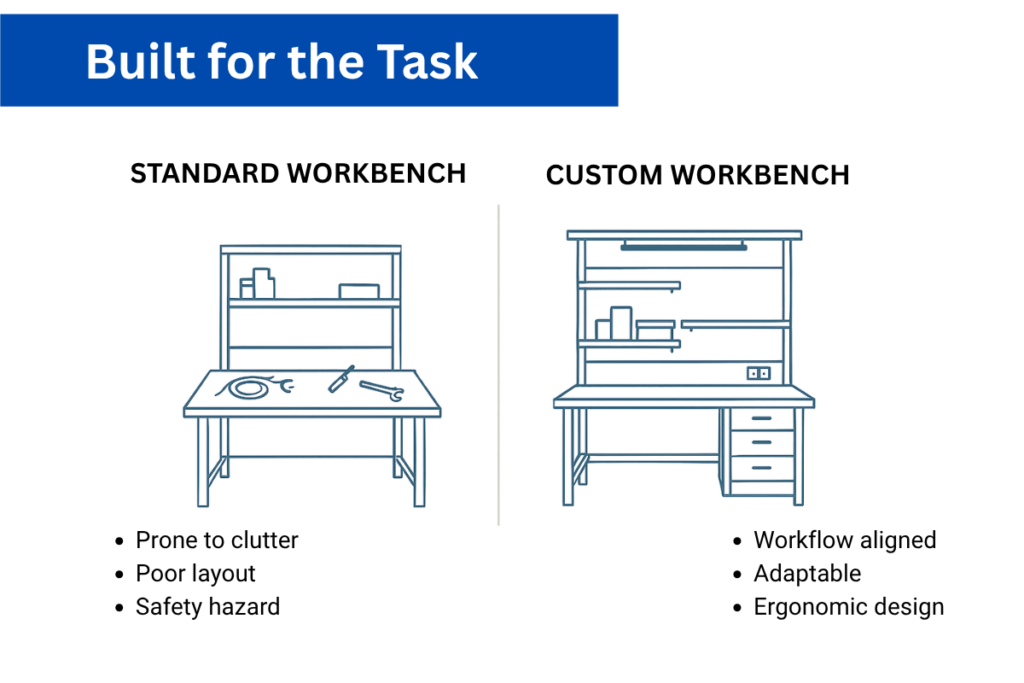

Built for the Task, Not the Other Way Around

Every operation has its own workflow. In a semiconductor cleanroom, that workflow centers on contamination control and precision handling. In a medical device assembly environment, the focus shifts to traceability and ergonomic consistency. In every case, the workbench must be designed around the process, never forcing the process to adapt to the bench.

Custom workbenches make this possible. Adjustable height, integrated shelving, task lighting, and modular accessories can be configured to match each operator’s responsibilities. Power outlets, data ports, or ESD protection can be placed precisely where they are needed. This tailored approach eliminates wasted motion, minimizes clutter, and reduces setup time.

When technicians do not have to adapt to their benches and tools and components are placed exactly where they should be, the result is measurable time savings and fewer process interruptions. Over hundreds of cycles a day, those seconds add up to real operational efficiency.

Supporting Collaboration and Adaptability

Modern manufacturing and laboratory environments rarely stay static for long. Processes evolve, new technologies emerge, and production volumes shift. The ability to reconfigure workstations quickly has become essential.

Custom workbenches designed with modular components give organizations that flexibility. Benches can be rearranged, expanded, or re-equipped without significant downtime.

For example, a biotech team developing diagnostic kits may need to shift from small-batch R&D work to scaled assembly. A modular bench system can grow with them, allowing new stations or accessories to be added seamlessly.

This adaptability supports collaboration as well. Teams can reconfigure work areas for shared projects or cross-functional workflows, then return to individual setups when needed. The workspace becomes a living system that responds to each project’s demands, not a fixed structure that limits innovation.

Ergonomics: Protecting People and Productivity

Efficiency is not just about speed. It is also about sustainability. Over time, repetitive motion, awkward reaches, or poorly positioned tools can lead to fatigue or injury. Custom workbenches that prioritize ergonomics help prevent these problems. Adjustable heights, accessible storage, and well-placed controls reduce strain and improve comfort.

Employees who work comfortably can stay focused longer and maintain consistent output. Fewer workplace injuries also mean less downtime and turnover. For companies that depend on skilled technicians, protecting their well-being is as critical as maintaining their equipment. A thoughtfully designed workstation demonstrates that commitment in a visible, daily way.

Clean, Safe, and Compliant

In industries where contamination control or regulatory compliance is part of daily operations, custom workbenches play a vital role. Surfaces must resist corrosion and be easy to sanitize. Materials may need to meet specific cleanliness or ESD standards.

Custom fabrication allows these requirements to be integrated from the start rather than added as afterthoughts.

- Aerospace and defense clients often need ESD-safe environments and integrated grounding systems.

- Biotech labs may require stainless-steel or powder-coated surfaces to withstand harsh cleaning agents.

- Medical device manufacturers depend on clean, smooth surfaces that prevent particulate buildup.

The right materials and construction details ensure that each bench not only supports efficiency but also compliance, safety, and long-term reliability.

The Long View: Efficiency Through Longevity

True efficiency is more than short-term speed. It is about creating systems that stay reliable over time. A custom workbench built with durable materials and designed for easy maintenance will deliver value for years. It can evolve with new tools and technologies rather than being replaced.

That longevity reduces costs, simplifies facility planning, and supports consistent operations across product lifecycles. It also reflects a philosophy many high-performance industries share: invest in quality upfront to gain stability later.

From Design to Daily Impact

Custom workbenches might start with dimensions and materials, but their real impact is measured in the work they enable. They let teams focus on precision and productivity, not on adapting to limitations.

When designed collaboratively, considering the workflow, the people, and the environment, they become the quiet foundation that keeps operations running efficiently.

Efficiency does not happen by chance. It is the result of deliberate choices about how space, tools, and people come together. A custom workbench embodies that balance. It is not just a surface to work on; it is a partner in getting the job done right, every time.

Ready to Build a More Efficient Workspace?

Partner with Bench-Tek to design a workstation built around your team’s exact needs. Whether you need modular flexibility, ergonomic precision, or cleanroom-ready construction, our experts can help turn your workflow challenges into lasting solutions.

Contact us today to start your custom workbench design conversation.

Key Takeaways

- Fits your workflow. Designed around how your team actually works.

- Adapts easily. Modular setups change with your process.

- Supports comfort. Ergonomic features reduce strain and fatigue.

- Built for compliance. Materials meet industry and safety standards.

- Lasts for years. Strong construction delivers lasting value.