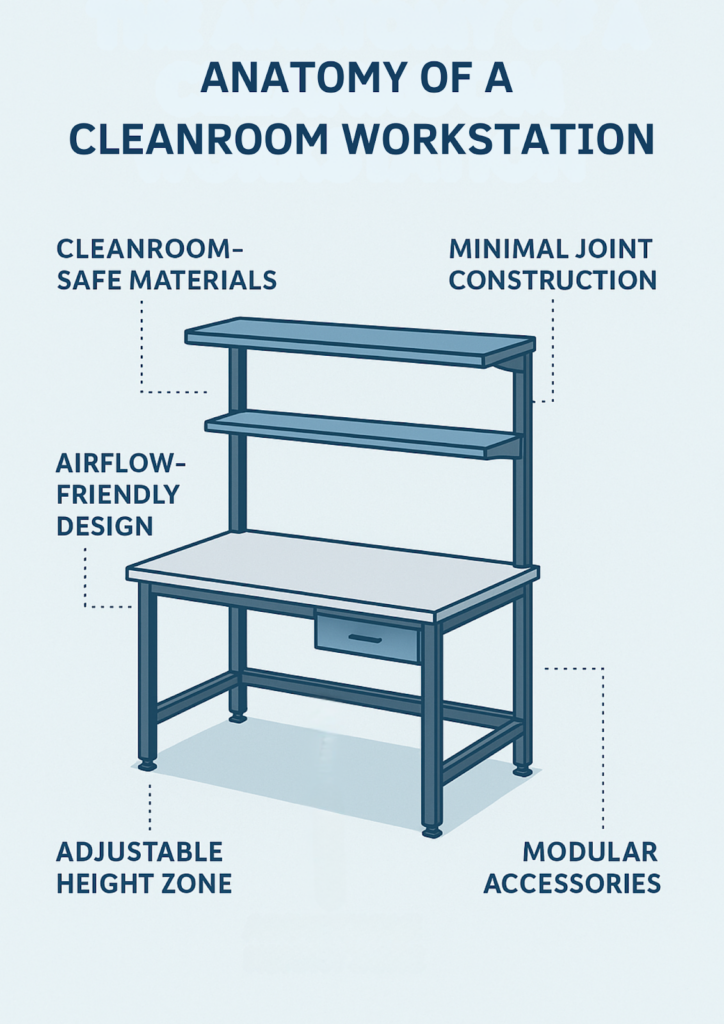

Cleanrooms reward the details. Every surface, movement, and material affects how well a space maintains its classification. A workstation or workbench is often the anchor of that environment, so it must do more than just hold equipment. It needs to support compliance, maintain smooth workflows, and withstand constant cleaning without hesitation.

Below is a clear, practical look at what makes a workstation genuinely cleanroom-ready.

Materials Built for Cleanroom Reality

In a controlled environment, a surface is only as good as its ability to stay clean. The top priorities are always the same:

- Low particle generation

- Smooth, nonporous finishes

- Resistance to chemicals used in daily cleaning

- Strength under repeated sanitation cycles

Stainless steel remains one of the most reliable choices due to its exceptional durability, ease of disinfection, and consistent performance over time. Cleanroom-grade laminates also work well for applications that require a lighter feel or a specific surface behavior. The goal is simple. Choose materials that do not degrade or absorb contaminants, and validation becomes far less painful.

Stable, Clean, and Predictable Construction

Cleanroom workbenches must remain stable during delicate processes to ensure accuracy and precision. Movement creates variables, and variables strain compliance.

Look for frames with high rigidity, dependable welds or fasteners, and minimal joints where debris can collect. Rounded edges help technicians clean quickly. Predictable layouts help everyone follow SOPs with less effort.

When the bench feels stable, operators stay focused and workflows become far more repeatable.

Height Adjustability and Ergonomics That Protect Precision

Cleanrooms demand consistency. Ergonomics plays a massive part in achieving that. Adjustable-height benches and well-planned tool placement reduce strain and help operators maintain a steady hand throughout long tasks.

A workstation that fits the person, not the other way around, is a quiet advantage in any controlled environment. Better comfort typically leads to improved compliance and fewer mistakes.

Layouts That Respect Airflow

Laminar airflow and filtration systems only function correctly when furniture does not obstruct them. A cleanroom bench should support that airflow pattern rather than disrupt it.

This means thinking ahead about:

- Undersurface clearance

- Shelf height

- Equipment locations

- Whether solid or perforated surfaces are needed

Small layout decisions help maintain proper air movement, reduce turbulence, and keep particle counts within limits. When airflow is respected, validation teams breathe a little easier.

Modular Systems That Grow with the Space

Cleanrooms do not stay static. Products evolve, processes change, and layouts shift to meet new requirements. Modular workstations keep pace without forcing major rebuilds.

Adjustable shelving, interchangeable accessories, and expansion-friendly frames let teams refine processes without disrupting validated areas. A modular approach is an investment in long-term adaptability, not just today’s setup.

Cleanability Above Everything

A bench can be technically impressive, but if it is difficult to clean, it becomes a liability. Cleanrooms require surfaces that wipe down quickly, joints that do not trap particles, and components that withstand aggressive cleaning routines.

Simple geometry often wins here. Fewer hidden corners mean faster and more reliable sanitation. When the bench cleans easily, compliance becomes a natural part of the workflow.

Ready to Build a Cleanroom Workstation That Works the Way You Do

If you need a workstation engineered for your cleanroom requirements, Bench-Tek can help. Our team works closely with you to understand your process, your environment, and the day-to-day demands your operators face. We develop customized, cleanroom-ready workstations and workbenches that support precision, simplify cleaning, and fit seamlessly into your controlled space.

If you are exploring options or planning a new layout, Bench-Tek is here to guide you through the details and ensure your setup is tailored to your workflow from the start.

Key Takeaways

- Cleanroom workstations need materials that resist chemicals and do not shed particles.

- Stability and ergonomic design help teams maintain precision.

- Airflow-friendly layouts reduce contamination risk and support validation.

- Modular systems keep cleanrooms adaptable without significant disruption.

- Easy-to-clean surfaces protect long-term compliance.